Milwaukee SHOCKWAVE

WHY CHOOSE A MILWAUKEE SHOCKWAVE DRILL BITS?

Milwaukee Shockwave is Milwaukee’s heavy duty impact driver accessory line. The Milwaukee Shockwave range contains hundreds of driver and drill accessories including but not limited to:

Shockwave sets, Driver Bits, Hole Saws, Nut Drivers, Step Bits, Drill Bits, Sockets and Adaptors and Bit Holders and Extensions

We all know most bits on the market are here today and gone tomorrow. The balancing act is always how long will a drill bit last vs how much it costs. Some people prefer buying cheap bits in bulk and some prefer to buy better quality bits that last long. Shockwave bits are the latter. These bits are a bit of bit magic!

Milwaukee claims that their impact and drill bits will outlast the competition by up to 30x. Bold claim but they back it up to be honest. What bits do you know to come with a warranty!? These ones do. That should tell you all you need to know about their build quality.

Here at ITS we stock the majority of the Milwaukee Shockwave range and are always on the lookout to increase our catalogue.

SO WHAT IS MILWAUKEE SHOCKWAVE – IN SIMPLE TERMS?

I thought about a couple ways to simplify shockwave and figured the simplest way to explain would be to break down Milwaukee’s shockwave page and each of their key selling points.

WEAR GUARD TIP™ EXPLAINATION

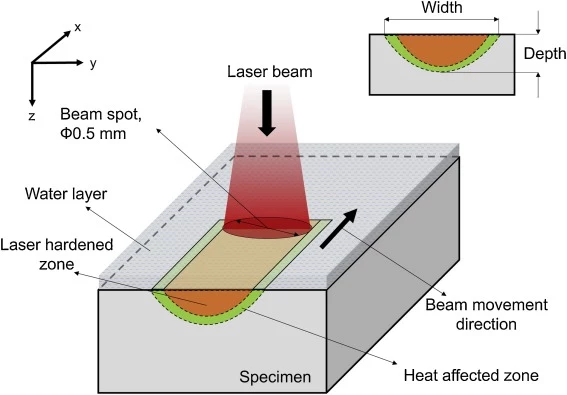

Shockwave bits go through a process known as Laser Hardening. Laser hardening is a heat treatment process or surface hardening process in which a laser beam is used to heat the surface of a metal part and then let it quickly cool down in surrounding air.

Laser hardening is the process of firing a laser at a metal to rapidly heat and cool the surface. This technique strengthens the bonds in the metal creating a tougher compound. The benefit of using a laser for this is the ability to process complex shapes and sizes. Laser hardening increases hardness and wear resistance creating a tougher and longer lasting metal alloy .

This essentially means that the tips of the bits are reinforced by a laser making the steel stronger and less likely to snap whilst being used. So for your money you’re getting a bit that lasts longer and stays sharper.

CUSTOM ALLOY76™ STEEL EXPLANATION

Custom Alloy76™ Steel is the metal used to create Milwaukee’s shockwave bits. A Custom Alloy steel is a refined steel using various types of ferrous metals in varying ratios to change the properties of a compound.

Adding different combinations and proportions of elements gives steel different characteristics. Elements such as vanadium, silicon, chromium, titanium, copper, cobalt, tungsten and aluminium are used in the process which depending on the proportions can increase the strength of steel.

Asking Milwaukee what Custom Alloy76™ steel is, is akin to asking KFC’s colonel for the 9 spice herb recipe, you just cant do it. But by understanding what a Custom Alloy Metal is, we can understand what Milwaukee means when they claim that their bits last 50x longer than others, depending on the alloy this is entirely possible.

OPTIMISED SHOCK ZONE™ EXPLAINED

The Shock Zone as Milwaukee calls it describes the long “neck” that many impact bits have these days.

The longer “neck” of the bit flexes and moves giving the bit more leeway and room for built up energy to escape vastly increasing the durability and longevity of the bit.