If you’re in the trade and you’ve never heard of a brushless motor then you’re really not trying hard enough! They’ve been the talk of the town for a couple of years now and most of the big power tool manufactures have joined the party and started to produce drills and drivers that have done away with the old brushed motors of the past. In doing so they claim to be able to get more power out of the drills themselves and also prolong the lifetime of their batteries per charge in most applications.

HOW DOES A BRUSHLESS MOTOR WORK?

The ultimate reason that a brushless drill is able to offer extended runtime and additional ‘capacity’ is because of the removal of the carbon brushes that until recently had been a cornerstone of all DC motors. These carbon brushes were used to transmit the electrical current from the power supply into the motor; they were what fundamentally ‘turned’ the motor. The issue with this technique is that over time the motor spinning would wear away at the carbon brushes and they’d eventually need to be replaced. Also on top of that when the motor span and hit the brushes it would generate heat and friction – both of which are forms of wasted energy. So in roundabout way that means that the energy created by the battery wasn’t being put to the best use, because as I say some of it would be wasted on friction and heat.

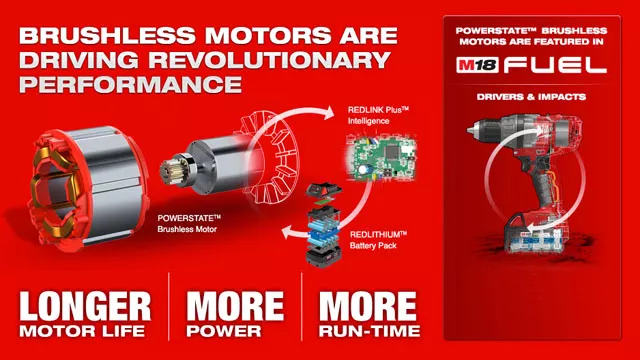

It was in an attempt to get more out of the battery that some clever science guy invented the brushless motor. Instead of having the electrical current sent into the brushes and then transferred to the motor, a brushless model has a computer chip that gets the current from the battery, which then controls a number of magnets that are housed around the DC motor. These magnets have their own electrical charge and the computer chip is able to manipulate that charge so each magnet is optimised to keep the motor turning at whatever rate the user requires.

WHAT ARE THE BENEFITS OF A BRUSHLESS MOTOR?

Because these motors no longer have the carbon brushes of before, we should start to see a variety of improvements in performance.

1) Increased Runtime – This is the most important to the modern day tradesman. Because the battery power is no longer generating wasted energy like friction and heat, more of the power actually goes into whichever application you’re doing. It follows that your battery will actually last longer doing that job per charge than it would do were it a brushed motor. Most manufacturers have suggested that the brushless equivalents are able to achieve on average about 33% more runtime per charge and up to 50% more on certain jobs.

2) Increased Power and Speed – Another positive of not having any of the battery power wasted on friction and heat is that your power tool is able to put a higher percentage of the battery power into the application than before. This means that your tool will be able to work a bit faster and achieve a bit more in terms of power, making your jobs that little bit easier.

3) Longer overall life of your tool – The savage reduction of the heat and friction caused by the brushes has one further benefit. It will actually prolong the life of your tool itself. Firstly there are no brushes so you’ll never need to send off to get a new pair, but also the wearing that takes place on the brushes also takes its toll on the motor itself over time (Although it would take an awful lot of use to start doing real damage). With that in mind you can see how a brushless motor would prolong the lifetime of your tool much more than a brushed model would.

4) Smaller and Lighter – A brushless motor is lighter than a brushed one and therefore brands will be able to produce lightweight models which will be far easier to work on all day. In addition it can be made smaller than a traditional brushed motor, so again brands will be able to make smaller tools, allowing you to access difficult areas.

To sum up – Less wasted energy on heat and friction – No brushes to replace – Up to 50% increase in runtime per charge – Long tool lifetime – Increase in speed and power – Smaller and lighter tools Well there you go a fairly decent run through of what a brushless motor is and how it will affect the performance of your tools in the future. Hopefully that gives you a better idea of what you get for your money and allow you to decide if you want to go brushless of not. If you have any questions about brushless motors or tools please drop an email to [email protected], phone us on 020 8532 5000 or connect with us on twitter, facebook or google+.